Computerized Maintenance Management System (CMMS)

Empower Maintenance. Maximize Uptime.

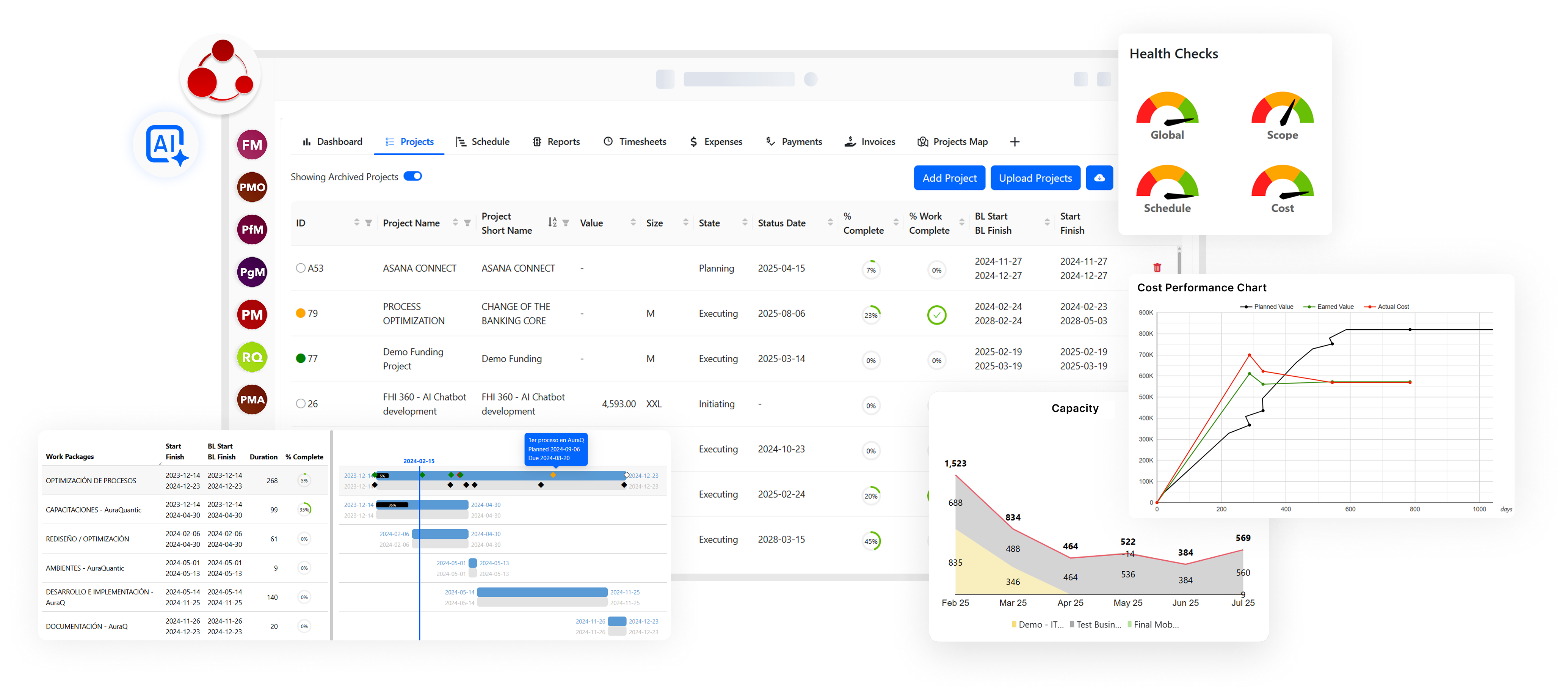

CMMS is a comprehensive Computerized Maintenance Management System (CMMS) tailored to transform how organizations manage maintenance—from assets and inventory to work orders and compliance. Built by PlusInfosys, CMMS brings clarity, control, and efficiency to maintenance operations.

Core Features of CMMS

Inventory Management

Maintain accurate tracking of parts and assets, ensuring seamless availability when needed.

What Is a CMMS?

INDUSTRY STANDARD EXPLAINED

A CMMS centralizes maintenance workflows, enabling teams to manage work orders, monitor asset health, track inventory, schedule preventive maintenance, and analyze KPIs—all within a unified platform. It serves as the command center for maintenance operations, helping organizations reduce downtime, lower costs, and improve overall efficiency.

Why CMMS Stands Out

Tailored for PlusInfosys Expertise

Developed with deep insights from enterprise-grade maintenance requirements.

Inventory-Centric Precision

CMMS's inventory module ensures parts and spares are efficiently tracked—reducing delays and enhancing readiness.

Scalable & Customizable

Designed to adapt across industries—from manufacturing floors to facilities management environments.

Seamless Data Management

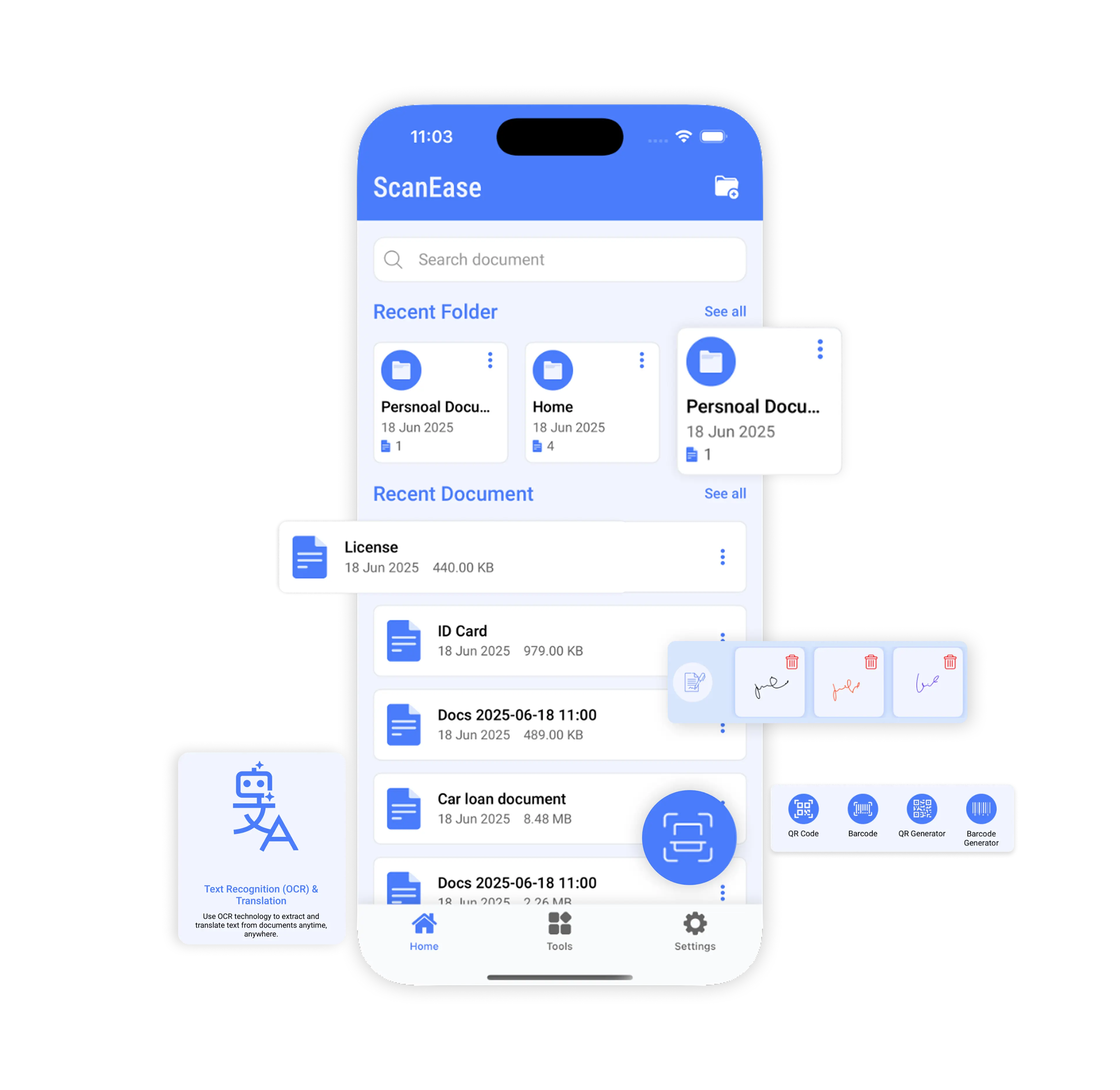

Centralization of maintenance data simplifies compliance, reporting, and analysis.

Benefits You Can Expect

Optimized Maintenance Efficiency

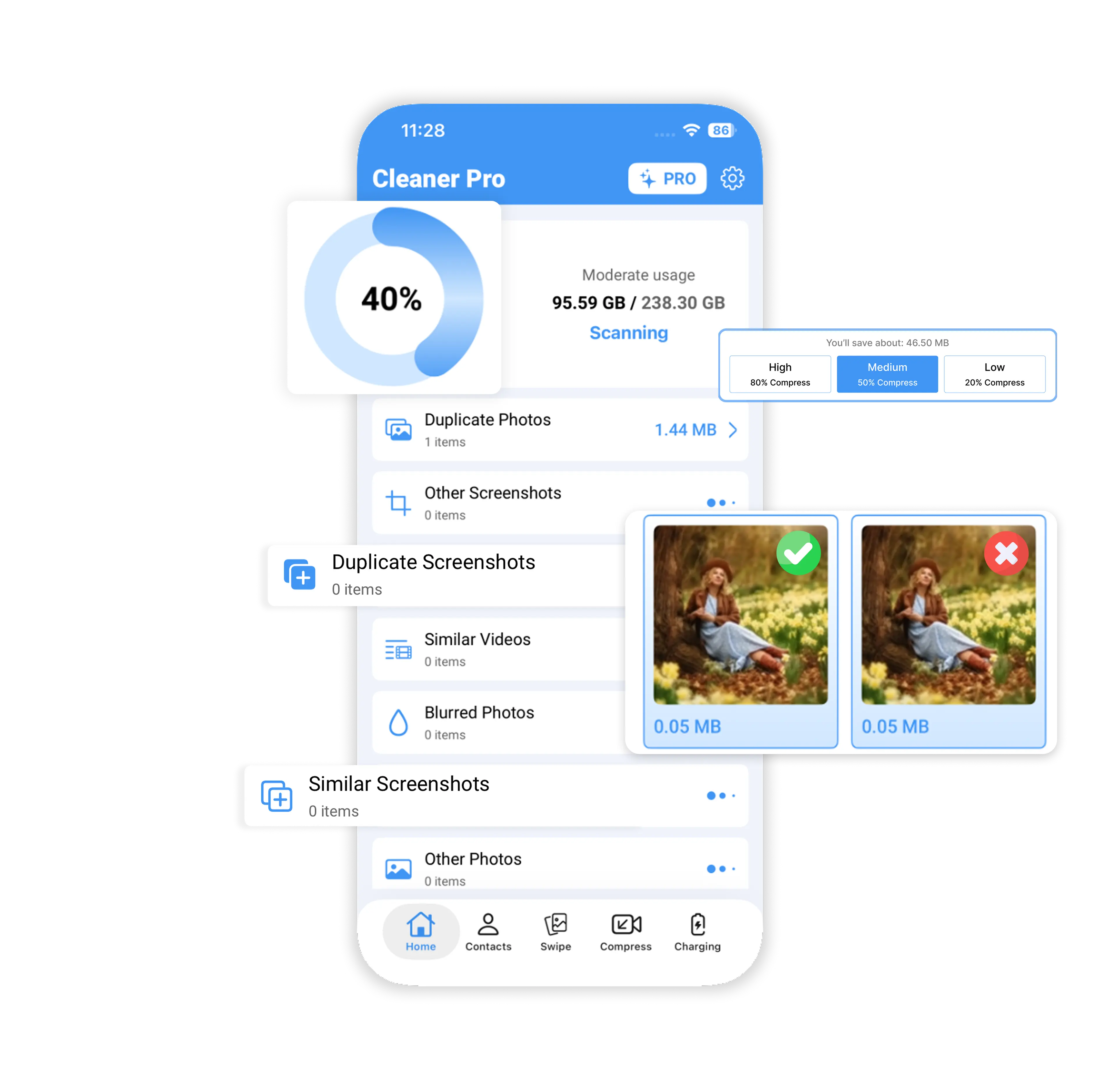

Automate key processes with centralized work orders, asset tracking, and inventory control.

Improved Asset Uptime

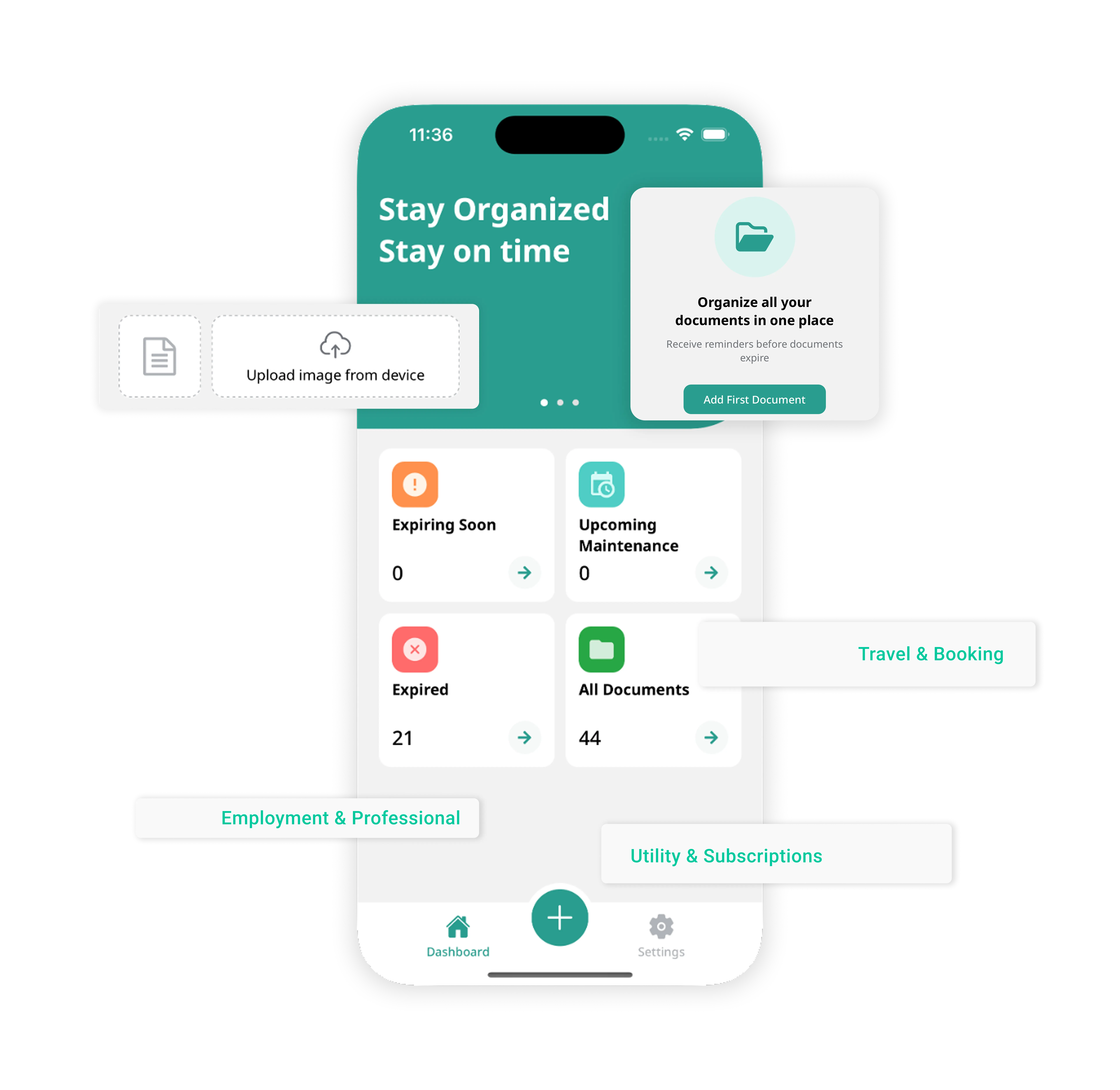

Plan and track maintenance more effectively, reducing unplanned downtime and extending asset life.

Data-Driven Insights

Leverage dashboards and reports to monitor KPIs like MTTR, asset health, and inventory trends.

Compliance Ready

Keep thorough records and audit trails for regulatory needs and accountability.

Who Benefits Most from CMMS?

Manufacturing Plants

Ensure machinery efficiency and minimize production disruptions.

Facilities & Infrastructure Managers

Oversee HVAC, utilities, and building maintenance systematically.

Industrial & Heavy Equipment Maintenance

Gain control across complex asset ecosystems.

Maintenance Service Providers

Monitor, report, and act on equipment issues across client sites.

Everything You Need to Know

A CMMS (Computerized Maintenance Management System) is software that centralizes maintenance operations, allowing organizations to manage work orders, assets, spare parts, preventive schedules, and compliance reporting from one platform.

By enabling preventive maintenance scheduling, asset health tracking, and real-time work order management, CMMS reduces unplanned downtime and helps extend the lifespan of critical equipment.

CMMS is highly versatile and supports manufacturing, facilities management, heavy equipment maintenance, and service providers, making it ideal for organizations of any size with assets to maintain.

Yes. CMMS maintains detailed records, audit trails, and maintenance logs, ensuring organizations meet industry regulations and compliance standards with minimal effort.

The system's inventory management module tracks parts, spares, and stock levels in real time, helping teams avoid shortages, reduce delays, and optimize procurement.